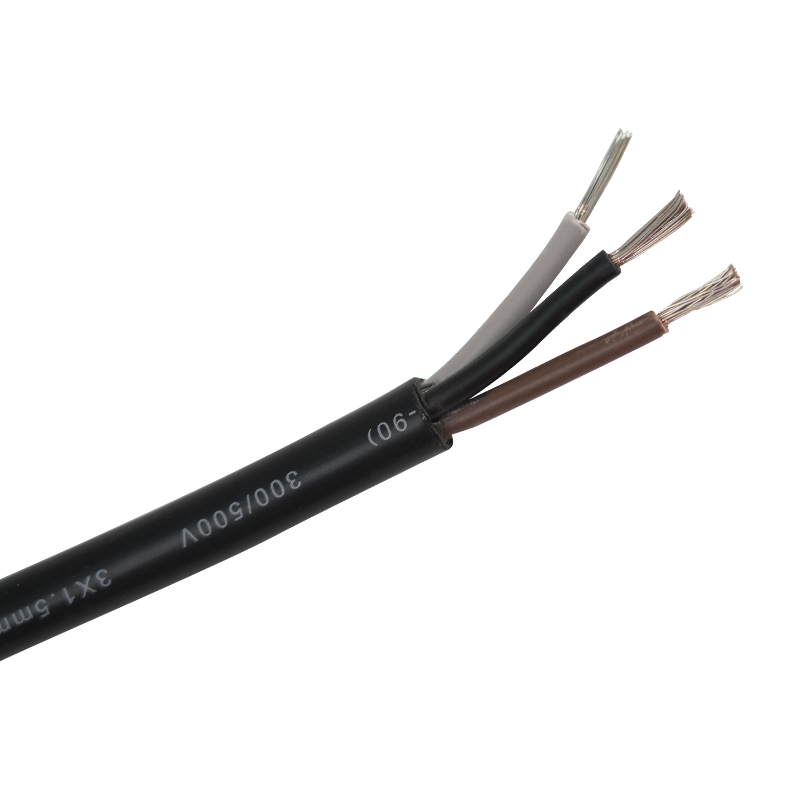

Ang silicone sheathed cable ay isang multi-core cable na gumagamit ng silicone goma bilang materyal na kaluban. Ito ay may mahusay na mataas na paglaban sa temperatura, mababang paglaban sa temperatura, paglaban sa panahon at kakayahang umangkop, katatagan ng kemikal, at proteksyon sa kapaligiran. Na -rate na boltahe 600/1000V, na -rate na temperatura -60 ° C hanggang 180 ° C, ang conductor ay hubad na tanso o tinned tanso na wire, ang pagkakabukod layer ay Ang silicone goma, at ang kaluban ay silicone goma din.

Mga lugar ng aplikasyon

1. Mataas na temperatura ng kapaligiran: Mataas na kagamitan sa temperatura sa metalurhiya, paggawa ng salamin, keramika at iba pang mga industriya.

2. Kagamitan sa Mobile: Mga Robot, kagamitan sa automation at iba pang mga okasyon na madalas na gumagalaw.

3. Kagamitan sa Panlabas: Mga kagamitan sa panlabas na kuryente tulad ng solar energy at enerhiya ng hangin.

4. Kagamitan sa Medikal: Panloob na koneksyon ng mga medikal na instrumento at kagamitan.

5. Mga gamit sa Bahay -bahay: Mataas na kagamitan sa temperatura tulad ng mga electric blanket at electric oven.

6. Aerospace: Mga koneksyon sa elektrikal sa matinding mga kapaligiran tulad ng sasakyang panghimpapawid at satellite.

Mga karaniwang modelo: YGZ, YGZ-GL (na may Braided Sheath)

Saklaw ng pagtutukoy: 2*0.5mm² ~ 3*240mm²

Ang mga silicone sheathed cable ay malawakang ginagamit sa iba't ibang mga mataas na temperatura at kumplikadong mga kapaligiran dahil sa kanilang mahusay na pagganap.

Silicone heating cables kumakatawan sa isang sopistikadong solusyon sa pamamahala ng thermal na idinisenyo upang maghatid ng pare-pareho, maaasahang init sa mga kapaligiran kung saan napatuna...

READ MORE